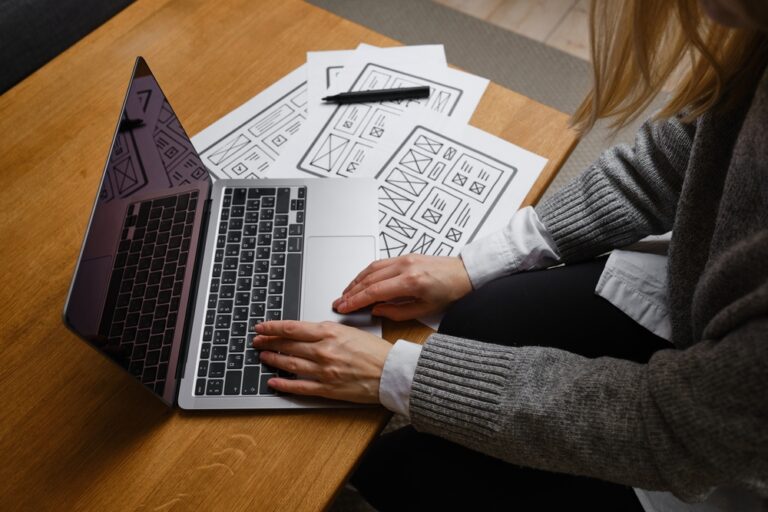

In the design and product development world, prototyping plays a crucial role. It bridges the gap between concept and reality, allowing designers, startups, and tech enthusiasts to bring their ideas to life effectively and efficiently. At Concept 274, we understand the importance of prototyping in product development. Our goal is to show you what is prototyping and guide you through the myriad of prototyping methods available and highlight the benefits each brings to the table.

Understanding Prototyping

Prototyping is the process of creating an early model of a product to test and validate design concepts. It enables teams to experiment with ideas, identify potential issues, and make necessary adjustments before moving into full-scale production. This iterative approach saves time and resources and enhances the final product’s quality.

Exploring Different Prototyping Methods

3D Printing

Description: Also known as additive manufacturing, 3D Printing creates physical objects by building layer upon layer of material based on a digital 3D model.

Benefits:

- Rapid Iteration: Allows for quick iterations and modifications.

- Complex Geometries: Can produce intricate designs that traditional methods can’t achieve.

- Cost-Effective: Reduces costs associated with traditional tooling and molds.

CNC Machining

Description: Using automated machines to cut and shape materials based on digital design specifications precisely.

Benefits:

- Material Versatility: Works with metals, plastics, and wood.

- Precision and Accuracy: Produces high-quality, functional prototypes.

- Scalability: Suitable for both low and high-volume production.

Rapid Prototyping

Description: Encompasses various methods such as stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM) to produce prototypes layer by layer quickly.

Benefits:

- Speed: Faster turnaround times compared to traditional manufacturing methods.

- Flexibility: Adaptable to different project requirements and materials.

- Cost-Efficiency: Reduces the cost of initial production runs.

Vacuum Casting

Description: A cost-effective method for producing functional prototypes in low volumes.

Benefits:

- Affordability: Lower costs for small batches.

- Quality: Produces high-fidelity prototypes that mimic final production parts.

- Versatility: Suitable for a variety of materials and finishes.

Sheet Metal Prototyping

Description: Cutting, bending, and assembling thin metal sheets to create prototypes of components or enclosures.

Benefits:

- Strength: Produces durable and functional prototypes.

- Precision: High accuracy in producing detailed parts.

- Customization: Easily modified to fit changing design requirements.

Soft Tooling

Description: Typically made from materials like silicone or epoxy, used for injection molding or other casting processes.

Benefits:

- Flexibility: Ideal for prototyping before committing to hard tooling.

- Cost-Effective: Reduces initial investment costs.

- Speed: Quick turnaround for small production runs.

Laser Cutting and Engraving

Description: High-powered lasers cut or etch acrylic, wood, or fabric materials.

Benefits:

- Precision: High level of detail and accuracy.

- Speed: Rapid production of intricate designs.

- Versatility: Can work with a wide range of materials.

Why Prototyping Matters

Enhances Collaboration and Innovation

Prototyping fosters a collaborative environment where designers, engineers, and stakeholders can refine a product. It encourages innovation by allowing teams to explore different design options and functionalities.

Reduces Time to Market

By identifying and addressing potential issues early in the development process, prototyping significantly reduces the time required to bring a product to market. This accelerated timeline is crucial in staying competitive in today’s fast-paced market.

Improves Product Quality

Testing prototypes ensures that the final product meets the desired quality and functionality standards. It allows for adjustments before committing to large-scale production, resulting in a superior end product.

Cost Efficiency

Investing in prototyping can lead to substantial cost savings in the long run. By catching design flaws and usability issues early, companies can avoid costly revisions during manufacturing.

Conclusion

Prototyping is an indispensable part of the product development process. It bridges the gap between concept and reality, enabling the efficient creation of innovative, high-quality products. Concept 274 specializes in various prototyping methods tailored to meet your specific needs. Whether you’re a designer, startup, or tech enthusiast, our expertise and network of suppliers will help you confidently navigate the complexities of product development.

Ready to turn your ideas into reality? Discover how Concept 274’s prototyping services can elevate your project. Visit our website to learn more and contact us to get started today.